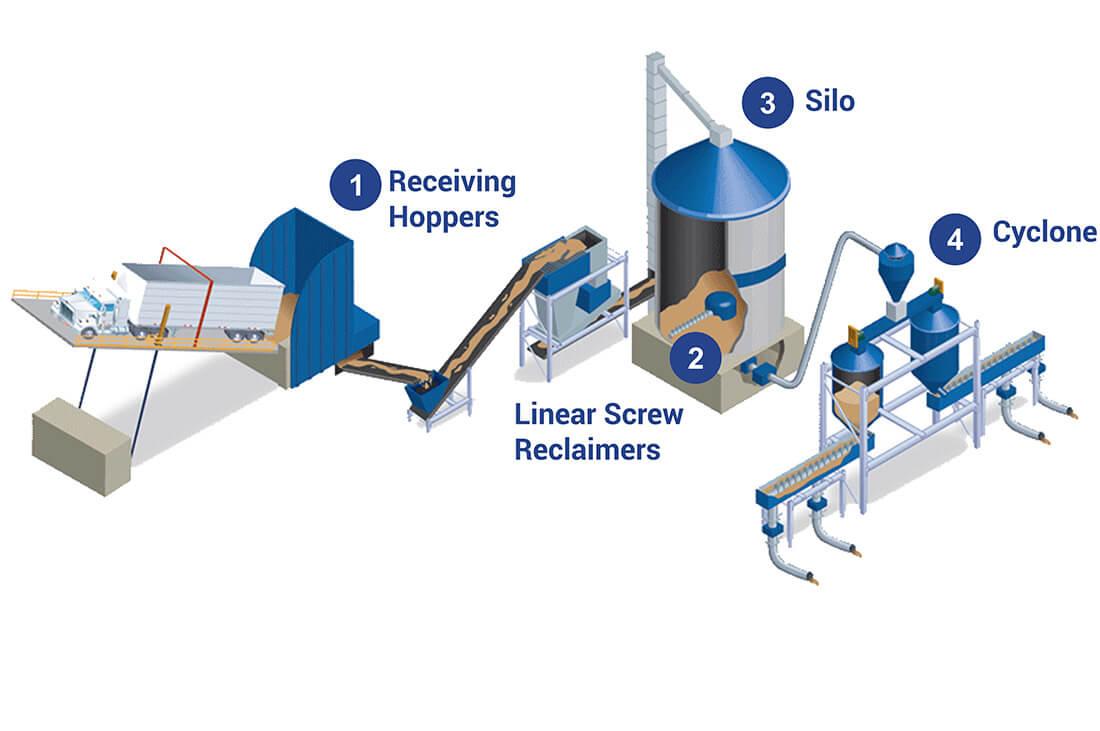

Pneumatic Conveying

Pneumatic conveying rates of more than 1,000 tons per hour can be achieved with this equipment. Jeffrey Rader designs ruggedly built rotary valves, cyclones, wear back elbows, ducting and blowers for tough, high-pressure, high-volume and abrasive pneumatic conveying applications.

Rotary Airlock Feeders

For feeding material into high/low pressure pneumatic conveying systems and boiler feed systems.

Mark III Elbows

Mark III flat back elbow for pneumatic conveyor applications is specially designed to reduce energy consumption, reduce wear and help eliminate fiber damage.

Blower Assemblies with Belt or Direct Drive

Jeffrey Rader uses standard positive displacement blowers to deliver a steady volume of air at constant velocity.

Rotary Airlock Feeders

For feeding material into high/low pressure pneumatic conveying systems and boiler feed systems.Efficiently move chips, bark and RDF bulk material over a long distance, elevate it in a short distance or inject woody material directly into a boiler. Pneumatic conveying rates of more than 1,000 tons per hour can be achieved with these systems. Jeffrey Rader designs ruggedly-built rotary valves, cyclones, wear back elbows, ducting and blowers for tough, high-pressure, high-volume and abrasive pneumatic conveying applications. With more than 50 years of experience and thousands of installations in pulp and paper mills around the world, Jeffrey Rader has the application knowledge to design and build your pneumatic conveying systems.